Ethylene tetrafluoroethylene (ETFE) is a fluorine-based polymer that is extruded into a foil-like roll. Similar to PTFE Fabrics, ETFE is a lightweight material that has gained popularity in recent years within the architectural design and construction communities. ETFE is now a progressive membrane utilized in lightweight structures, specifically as an effective replacement for glass and other more costly transparent materials.

ETFE is an extremely lightweight and transparent material. Its mass is approximately 1% of the weight of glass and a fraction of the cost, leading to an excellent replacement for glass in architectural designs. Additionally, due to the ETFE’s lightweight nature, the supporting steel can be significantly reduced in size, providing additional cost savings. With savings of up to 66% on structural steel, ETFE is a truly lightweight and cost-effective solution for a client looking to replace glass canopies or overhead glazing systems.

Highly translucent

The high light translucency (Tv) allows up to 95% light and can allow similar daylighting levels compared to glass. With the application of printed frits, ETFE can provide effective thermal heat gain resistance that can be measured as either a Shading Coefficient (SC) or Solar Heat Gain Coefficient (SHGC). This allows for similar heat gain controls to glass for both enclosures and canopy applications.

Versatility

A huge selling point of ETFE as a building material is its low flammability and self-extinguishing ability in the event of a fire. Fire-rated to ASTM E84 Class A, the EFTE foil shrinks back from the plume, which effectively vents the fire. Due to the substance’s chemical properties, there are no drops of molten material and little smoke produced in the event of a fire. Other advantages to ETFE over glass are that it is more flexible than glass so that higher magnitudes of deflection can be tolerated, as well as its shatterproof nature, making it a good material to use in overhead applications as well as earthquake-prone areas.

ETFE has proven itself in all climate conditions. It is resistant to temperatures from arctic temperatures upwards to over 200°F degrees. ETFE’s durability allows it to withstand high winds and snow loads.

ETFE-inflated pillows have been used on numerous inspired architectural designs and are typically in enclosure projects. ETFE can also be installed as a single-layer membrane for canopies and exterior cladding for facades.

LED lighting

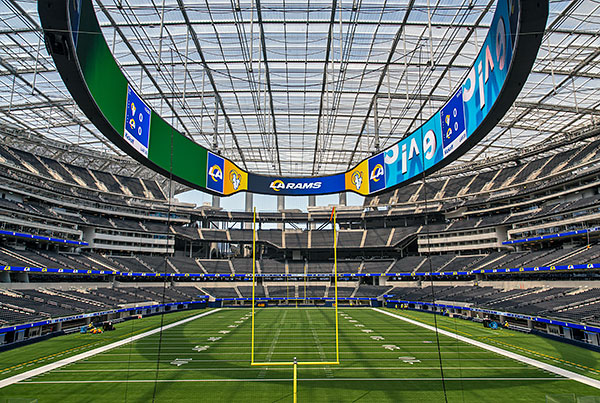

ETFE is an effective material to be illuminated at night using LED technology. LED lighting creates a dramatic effect making the structure a feature or landmark for development at night and during the day. Dynamic programmable LED lighting, capable of displaying messages, images, and even video, has been used on several of our projects with spectacular results. Our work on SoFi Stadium, Allianz Field, and the ATLNext Central Passenger Terminal Complex at Hartsfield-Jackson Atlanta International Airport are good examples of brilliantly designed structures that become incredible with the addition of LED lighting.

Low maintenance

Minimal maintenance is required on ETFE, making it a popular choice to work with. ETFE is 100% recyclable. The material is inert and unaffected by UV light, pollution, and adverse weathering, resulting in a long life expectancy. Due to its long lifecycle, ETFE is a preferred material for environmentally concerned designers.

Overall, ETFE has had a positive impact on sustainability within the construction industry. It outperforms glass and other transparent materials for insulation, weight, and cost.

Enclos Tensile Structures (ETS) has designed and installed many ETFE installations. See some of the fantastic structures we’ve built with ETFE in the gallery following this article.