Structure Type: Canopies

Project Scope:

Project Size: 59,775 sqft

Material: PTFE/ETFE

Location: Summerlin, NV

Completion Date: 2014

Market Segment: Functional & Commercial Buildings

Owner: Howard Hughes Corporation

General Contractor: VCC Construction

Architect: Altoon Partners

Structural Engineer: John Martin and Associates

Photo credits: Gary Taylor

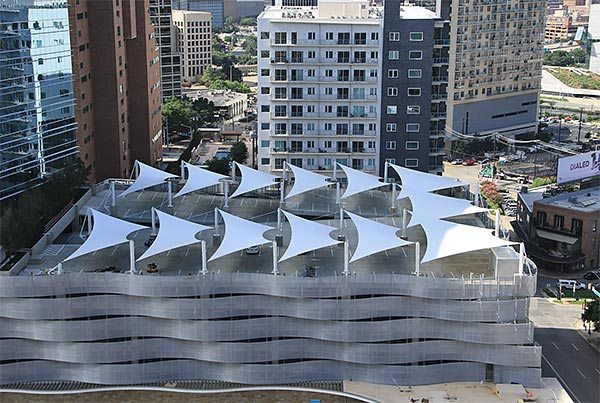

PFEIFER Structures completed construction of the Downtown Summerlin retail center in Summerlin, NV. The project features a massive fabric surface area of approximately 59,775 square feet of both PTFE and ETFE materials in two of the four “districts” that make up the mixed-use retail center. But the project is especially impressive because of the complex steel fabrication required to distribute the load. The Shops at Summerlin Centre is an outdoor business, entertainment, fashion, and retail district, part of a mixed-use development project initiated by the Howard Hughes Corporation in Summerlin, Nevada, in 2007.

Featuring 1,800,000 sq. ft. of retail space, construction on ‘The Shops’ broke ground in the summer of 2012. 506,591 lbs of steel (or 253 tons) support the fabric structures in the main retail area, District 2 and District 4. This equates to roughly 8.47 lbs/sqft, which is reasonably light for the amount of covered area. In many instances, tension structures are a contributor to the LEED evaluation through the use of effective design and reduction in the carbon footprint. All the steel is finished off-site at our facilities in Dallas and shipped in components ready for assembly on-site.

At the heart of the design is a uniquely large compression ring making up the main canopy. Most compression rings are round, but the conical shape of the Summerlin Shops main canopy called for an oval shape creating extremely large trusses, which created many laydown challenges at the manufacturing facility and a complicated fit-up on site.

In District 4, the compound curvature of the steel that makes up several freestanding fabric structures resembling graceful tail-less flying bat rays in the sky required extensive rolling and fit-up because every steel section had a different shape. It’s interesting to note that when viewing these particular structures from below, the grid-like steel was more for aesthetics than required to support the membrane. This was a requirement for the design team.

Twelve cantilevered tensile structures cover the four main walkways leading to the mast-supported main cone over the center of the shopping center’s courtyard. The tip of the main cone is ETFE. The transparent properties of this material were chosen to allow maximum light exposure to shine down on the shops below, as well as provide for an interesting uplighting effect for visual impact at night. The main conical structure had to attach to four different buildings while inducing minimal loads. Using the ring configuration helps reduce the load, as a ring is “self-resolving” in the horizontal direction and puts minimal loading onto the buildings.

The freestanding structures, 16 in all, are fabricated out of PTFE membrane.

Material Details:

- Fabricated Sheerfill II HT PTFE architectural membrane; white.

- Fabricated 250-micron ETFE film w/ “gray” printed frit.

- Finish painted structural steel. Powder-coated aluminum clamp system with stainless steel fasteners.

- Galvanized cables for Main Cone Canopy with PVC coating for cables in contact with the fabric.

- Stainless steel cables for Main Cone Canopy Cone Top Cable Net. Galvanized hardware and threaded rods where applicable.